A variable speed drive (VSD) is a device that controls the speed of a motor. It provides an interface between the electric machine and its control system, allowing you to specify the target speed and torque of your motor.

A soft starter, on the other hand, is used for new motors. Soft starters are characterized by their ability to reduce energy consumption while reducing vibration when starting a Variable Speed Dc Motors —they’re also more affordable than VSDs in some cases.

Why Use a Variable Speed Drive?

Variable speed drives are devices that can alter the speed of an electric motor. This is done by adjusting the voltage and frequency of power being sent to the motor.

- Reduced energy consumption: By operating at a lower speed, variable speed drives are able to save you money on energy costs. They do this by reducing or eliminating overload situations, which cause your Variable Speed Dc Motors to draw more current than needed for running at high speeds (and therefore using more electricity). You may even be eligible for rebates from utility companies in some states if you install one!

- Increased productivity: Variable speed drives can help increase productivity by lowering maintenance costs while maximizing performance. Reducing excess wear on your equipment means it will last longer and perform better over time―not just initially but also during its entire lifetime, which could be anywhere from five years up into decades when we’re talking about industrial processes like those used in factories or mines where horse power isn’t going anywhere anytime soon…

How Does a Variable Speed Drive Control Induction Motors?

The first thing that you should know about VSDs is that they use a controller to control motor speed. The controller uses sensors at the motor, which monitor things like load and temperature, to determine the appropriate speed of the motor. It then adjusts it accordingly in order to optimize performance for your application.

This is all done via feedback from the controller: it takes readings from its sensors and compares them with what it has determined as ideal conditions for your application (which are based off of predetermined settings). If there’s a difference between what’s happening at the moment and what should be happening according to those settings, then adjustments will be made until they’re equalized—this is where feedback comes into play as well as other processes involving calculations like PID (proportional–integral–derivative) loops or PID controllers.

When you change the speed at which your pump runs, you’re actually changing how hard your machine works to perform its task at any given time. The main advantage of Variable Speed Motor Drive over other types of drives is that it uses less energy than other types of drives because when it doesn’t need to push as hard it doesn’t use as much electricity; however there are some disadvantages such as increased noise levels due to higher speeds being possible in applications such as fans where vibration maybe an issue

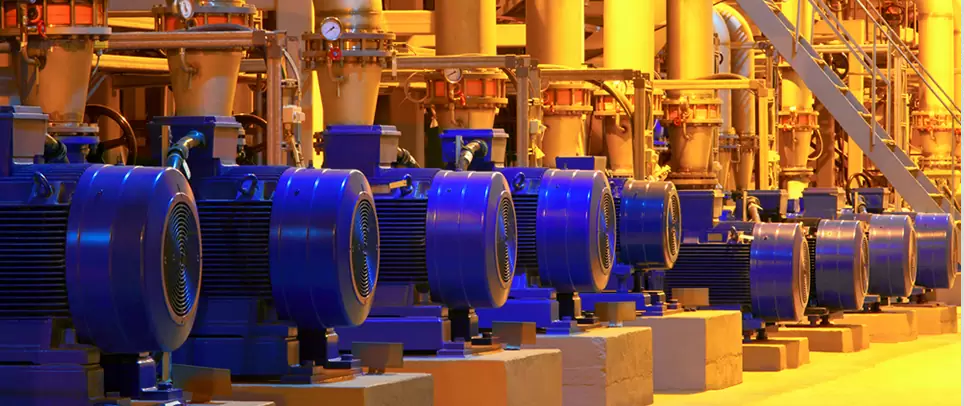

What Are Some Applications for Variable Speed Drives?

Variable speed drives can be used in a wide variety of applications where motors are used. Some of these applications include:

- Air conditioning systems

- Cooling towers

- Compressors and blowers

- Elevators, escalators, and conveyors

- Food processing machines

A variable speed drive is a method that adjusts motor speed to optimize performance for your application.

A variable speed drive is a method that adjusts motor speed to optimize performance for your application. This is often done by using an electronic controller to vary the angle at which the AC power flows through the coils of an induction motor in order to affect its magnetic field.

Why would you want to do this? Well, if you have a pump with too much horsepower, it might be operating inefficiently at times when there’s no need for all of that power. And if you have some other equipment on your site (like an air compressor) that needs more electricity than what’s available from the grid during peak hours (when everyone needs their appliances), then it makes sense not just for efficiency reasons but also cost-effectiveness ones as well!

Conclusion

Variable speed drives are a great way to get the most out of your Variable Speed Dc Motors, whether you’re running an industrial machine or just trying to save some energy in your home. They’re easy to install and can be used in a variety of applications. They may seem complicated at first glance, but once you understand how they work and what they do for you, they become much more straightforward!