When it comes to your business’s efficient and reliable operation, you can’t afford to take any chances. That’s why it’s important to partner with a temperature calibration services provider who can ensure your equipment is always operating within spec.

Instrument Certification Companies Can Provide You With The Essential Equipment

- Why Does My Device Need to Be Certified?

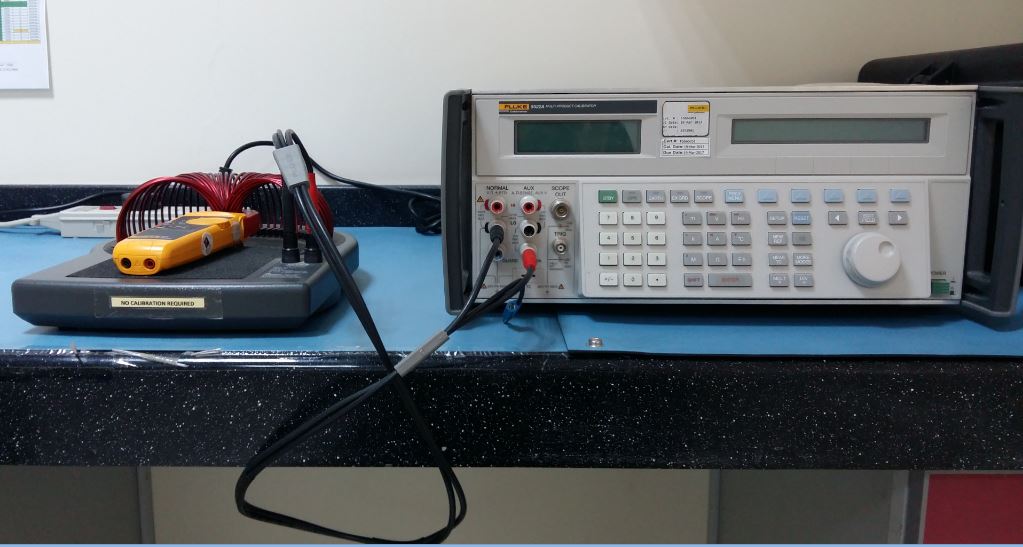

Temperature Calibration is the process of verifying and adjusting the output of a temperature measuring device by comparison to a known reference temperature. This is done to ensure that the device operates within its prescribed accuracy specifications. An accredited calibration laboratory must certify all temperature-measuring devices to ensure reliability and traceability. By calibrating your devices regularly, you can be sure that your measurements are accurate and consistent, thus ensuring the safety and quality of your products.

- Certification Benefits for Your Business?

Certifications offer a number of benefits to businesses. Perhaps the most obvious benefit is that certified equipment is operating within FDA and other regulatory compliance. This means that you can avoid costly fines and damage to your reputation for not complying with regulations. Certification can also improve your bottom line by helping you win more business and increasing the efficiency of your operations. When potential customers know that your equipment is certified, they have greater confidence in your products and services. Finally, certification helps you stay competitive by demonstrating that you are committed to quality and continuous improvement.

- How to Get Your Instrument Certified?

Instrument certification is the process of verifying that an instrument meets specific requirements and is calibrated correctly. The calibration process verifies the accuracy of an instrument by comparing it to a known reference value. This ensures that your instrument is always operating within its specified range, which can help prevent costly damage and downtime.

- Why You Shouldn’t Trust an Uncertified Technician?

While it may seem like an unnecessary expense, certification is an important investment that ensures the safety and accuracy of your equipment. When it comes to temperature calibration, it’s crucial that you only trust a certified technician. An uncertified technician may not have the proper training or knowledge to accurately calibrate your equipment, leading to inaccurate readings and potential damage.

- How to Recognize a Trained and Certified Technician?

When it comes to temperature calibration, it’s important to know that you’re entrusting the job to a trained and certified technician. Here are a few things to look for when choosing someone to calibrate your equipment:

– Are they certified by a nationally or internationally recognized organization?

– Do they have extensive experience in temperature calibration?

– Do they have a reputation for providing quality workmanship?

– Do they have a good understanding of your specific equipment and how it should be calibrated?

If the answer to any of these questions is no, you might want to consider finding someone else. When it comes to your business’s bottom line, you can’t afford to take any chances.

Conclusion:

Instrument certification is important to ensure that your devices are always calibrated and operating within the manufacturer’s specifications. Not only will getting your equipment certified improve its performance and Temperature Calibration, but it can also help protect your business from liability in the event of a malfunction or accident. With Temperature Calibration Services, you can trust that your devices will be in safe hands.