Hydraulic rams are a common part of industrial and commercial machinery, often used to lift heavy loads. They’re designed to hold pressure and withstand high pressures without becoming damaged. However, they can wear out over time if not properly maintained or inspected. Proactive Hydraulic Ram Repairs are important for ensuring that your machine is running smoothly without any downtime due to malfunctioning parts.

Let’s take a look at the hydraulic rams and why proactively maintaining them is so important

Hydraulic Rams are used in a variety of industrial and commercial applications.

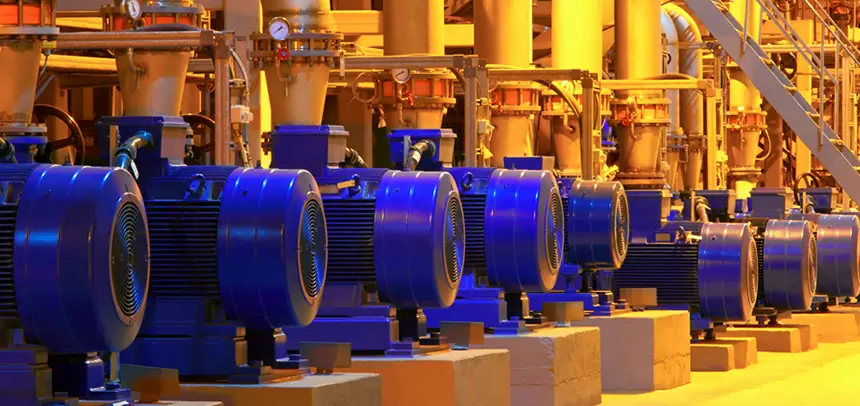

Hydraulic rams are used in a variety of industrial and commercial applications. They are used in construction, mining, agriculture, transportation and heavy equipment manufacturing industries.

Hydraulic rams are also used in a wide range of applications such as lifting loads or moving them from one place to another.

Designed for holding heavy loads

Hydraulic rams are a type of hydraulic machine that is used to hold heavy loads. Hydraulic rams are commonly used in construction, manufacturing, agriculture and other industrial applications.

They’re usually made of steel or aluminium and have pistons that compress a spring-loaded oil chamber when they’re compressed.

The proactive repair can prevent downtime and lost production.

Proactive hydraulic ram repair is a cost-effective way to keep your equipment running smoothly and prevent downtime. While it may seem counterintuitive, replacing parts before they fail can save you money in the long run. By proactively inspecting and repairing hydraulic rams, you can avoid unexpected downtime and costly repairs.

For example, if there is damage or wear on a hydraulic ram’s piston rod seal, this could lead to less-than-optimal performance. When the engine starts up again after being shut down for any reason. Especially if it has been running at high pressure for an extended period of time (like during peak production). If this condition goes unaddressed for too long without being repaired properly by trained technicians who specialise in rebuilding damaged seals correctly.

Using genuine OEM parts from trusted manufacturers then eventually will become necessary for them both. One because its lifespan has been shortened considerably due to improper care two because now that same part must be replaced before any further damage occurs. Which would otherwise result in costly repairs later down the road.

Preventing malfunctioning will help increase the life of your machine

Proactive hydraulic ram repairs are one of the best ways to prevent damage and extend the life of your equipment. By regularly inspecting your machine, you can identify any signs of wear or damage before it becomes a major problem.

This proactive approach will help keep your machinery running smoothly, which can save time and money in the long run.

Hydraulic rams should be routinely inspected for wear, damage and any other factors which may be causing them to wear down or reduce their effectiveness

Hydraulic rams are used in a variety of industrial and commercial applications. These machines are designed to hold heavy loads, but they can wear down over time. In some cases, this wear is caused by damage to the Hydraulic Filters itself in other cases it’s caused by other factors that affect its operation.

In either case, proactive Hydraulic Ram Repairs repair can prevent downtime and lost production. While also ensuring that your machine operates at peak performance levels throughout its lifespan. Preventing malfunctioning will help increase the life of your equipment, which means more money saved.

Conclusion

At the end of the day, it’s important that you keep your hydraulic rams in good working order. They’re an essential part of many different machines and they can help ensure that your operation runs smoothly and efficiently. If you want to know more about proactive repair services or just want some more information on how these machines work in general, then reach an expert.