Hydraulic Power Units or HPUs are very important in industrial machinery, especially when it comes to manufacturing processes that involve heavy machinery like cranes and excavators. To ensure that this machinery works efficiently, businesses need to have the best HPUs to power them.

Read on to learn more about the importance of HPUs and how they improve industrial machinery:

-

Basic Working Principle

Hydraulic power units, or HPUs, are devices that convert electrical energy into hydraulic energy. This allows industrial machines to operate more efficiently and productively. By understanding how a Hydraulic Pumps works, you can better appreciate its value to various industries. Here’s a look at how they function: When your car brakes, the discs in your vehicle wear down and need to be replaced from time to time.

-

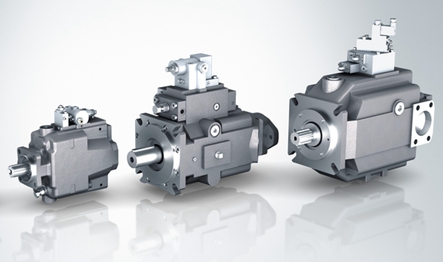

Types Of HPUs

Most hydraulic power units (HPUs) can be broken down into two main categories: planetary and variable-displacement. Planetary HPUs have a single crankshaft that transfers energy to other components by means of multiple gears; variable-displacement HPUs, on the other hand, employ an internal pump that’s driven by a multiple-stage turbine—which allows them to smoothly deliver high amounts of pressure across a wide range of flow rates.

-

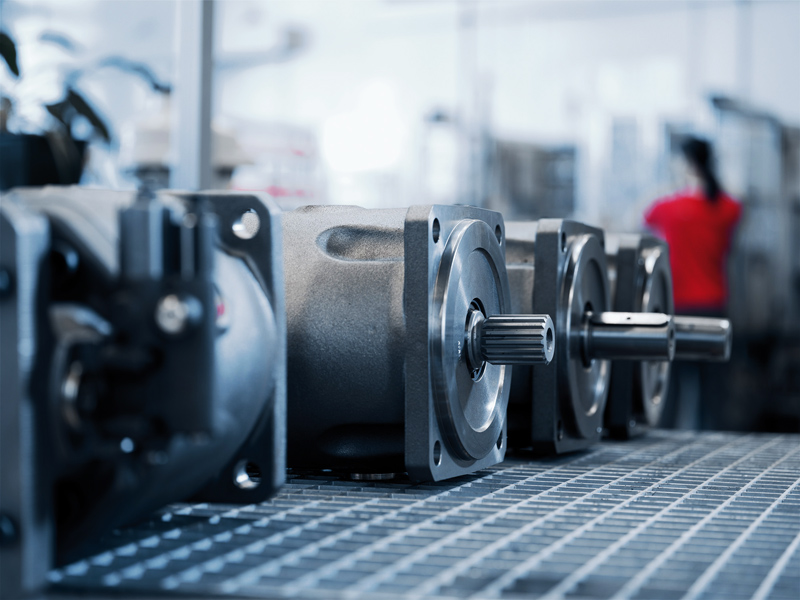

Applications Of HPUs

HPUs are commonly used to run hydraulic devices in industrial machinery, including cranes, excavators, dozers and elevators. A hydraulic device is any machine that uses hydraulic fluid to perform a specific function: excavation equipment need high-pressure water to move large boulders or dirt; elevators require low-pressure oil for smooth operation. A HPU creates high pressure by pulling oil from an underground tank; when released into a cylinder, it’s compressed. The force created can be used to power other machines or tools. It’s important to note that HPUs aren’t always necessary—many machines have small engines attached, which means they can operate on their own without help from a larger power source. However, some machines—such as those with massive amounts of weight—require assistance from an external source of energy.

-

Disadvantages Of HPUs

Despite their numerous advantages, there are several potential disadvantages to using HPUs. Their high initial cost is one factor that deters some companies from installing them on machinery. In addition, HPUs can be very bulky, which makes them difficult to install on smaller equipment. In addition, machine operators must be properly trained to use and maintain an HPU system. Lastly, a loss of power will cause all powered hydraulics to automatically shutdown or disengage.

conclusion:

Mechanical and hydraulic systems have been around for thousands of years. You might even say that they are both relatively primitive in their constructions. However, each has gained a following in its own right and is currently on par with modern technology. Both have been used to build some of man’s most impressive and sought-after industrial equipment, making them an important part of modern industry.