Variable frequency drives (VFDs) are certainly more common than ever before. The technology has been around for more than 100 years, but until recently it was used primarily in manufacturing and industrial applications. Now, however, VFD systems can be found in just about every industry imaginable—from power generation to oil refineries to airplanes and even medical devices.

In this article we’ll explore how Variable Speed Drive Motor work, how they’ve evolved over time, why they’re so popular today and how they might evolve in the future. We’ll also look at some of the ways that AC permanent magnet motors (also known as PM motors) have changed since their introduction five decades ago.

Early AC speed control

Early AC speed control was simple and straightforward, involving a motor with a variable-speed control (VSC) device. An operator would set a desired speed using the VSC, which then sent that command to the motor and drove it to that speed.

The first type of variable frequency (VF) drives were low-speed AC drives. As their name implies, these devices operate at low speeds and can be used for applications such as torque control on pumps or conveyors. A typical application is an air compressor where you want to vary the output pressure by changing its motor speed.

The process requires precise control over both voltage and frequency: if either one changes out of range, you’ll lose efficiency because it takes more power to run faster than necessary or slower than necessary. These systems use DC motors that require inverters with good harmonic performance; they also need controls that can provide accurate feedback signals so they stay within set limits as well as automatic shutdowns when those limits are exceeded.

Advanced automation

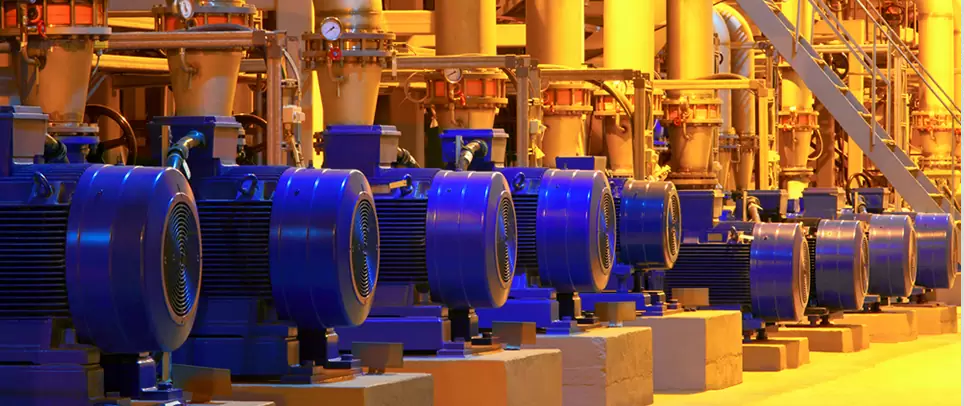

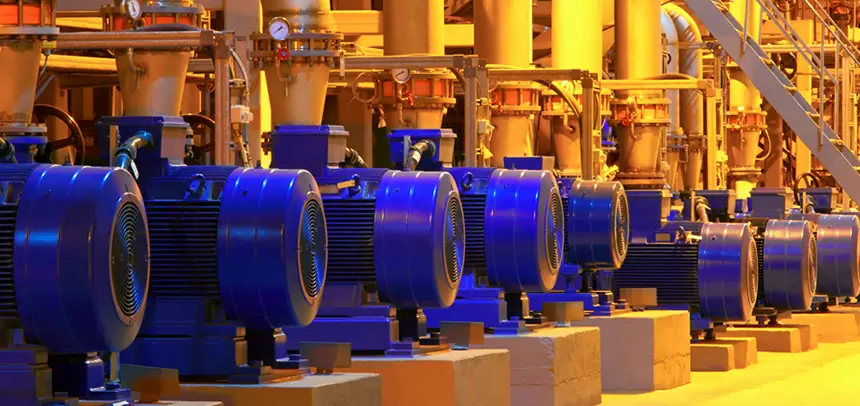

Variable frequency drives (VFDs) are used in a variety of applications. The following are some examples:

- To control AC motors. VFDs use variable frequency to regulate the speed and torque of an AC motor by varying the frequency of its incoming power source, which is typically 60 Hertz. Motor size and duty cycle determine how much energy it takes to operate the motor at certain speeds and loads, so VFDs can be used to increase efficiency by lowering operating costs for a given task.

- In industrial applications, VFDs can be found in everything from conveyor systems to machine tools; they help keep things running smoothly while reducing energy costs by up to 70%.

- In commercial settings such as factories or warehouses where there’s lots of heavy lifting going on around-the-clock (think forklifts), those who invest early often see huge returns down the road thanks to lower maintenance costs associated with their new technology investments.”

Advanced control modes

When it comes to programming, VFDs come in many forms. They can be programmed to control many different processes, from variable speed drives on pumps and fans to conveyors, motors with loose couplings and other equipment.

Programmers typically use a computer to write a program that tells the VFD when and how long to energize each phase of the motor. This is known as pulse-width modulation (PWM).

Typically, this process is done in the field—not in the factory—by an operator rather than a technician or engineer (unless there’s some special customization involved). The result is enormous savings for manufacturers because they no longer have to pay for expensive engineering services or wait for lead times from their suppliers.

Connected VFDs

Connected drives are used in many more applications than before. They can be connected to the internet, cloud, other equipment and even the user. Connected VFDs have become a standard for critical applications such as aircraft engine controls and chemical process control systems where safety is of utmost importance.

The remote access capabilities of these drives allow users to monitor and manage their systems from anywhere in the world via an internet connection or phone app. This provides more flexibility for engineers who may not always be on site at a plant or facility when problems arise.

VFD systems as a preferred solution

Variable frequency drives (VFDs) can be a great solution for your application. They offer many advantages over traditional drives, including:

- Lower maintenance costs – because of their reliability, VFDs require less downtime for service and repair.

- Improved efficiency – VFDs use less energy to achieve a given output than traditional AC motors do. This means lower operating costs and reduced greenhouse emissions as well as higher equipment availability due to fewer breakdowns requiring costly repairs or replacements.

- Higher performance – with more options available than ever before, you’re sure to find one that meets your needs while delivering more power at lower RPM levels than other motors provide today—without having to sacrifice anything on quality or durability!

Conclusion

The technology behind Variable Speed Drive Motor has come a long way. From early AC speed control to today’s modern devices, VFDs are more advanced than ever before. They offer many benefits like safety, reliability and efficiency that make them the preferred solution in many applications.